FLW Monitoring System

WASTELESS Open access Blockchain

Developed by WIISE

The WASTELESS Blockchain will host an electronic ledger, developed on the basis of the FLW Standard of the FLW Protocol (the first international standard for measuring and monitoring food loss and waste), in which food business operators can enter and monitor data and information related to their processes and side streams, including FLW. The data entered is reported based on the Lansink scale and the Waste Hierarchy, to demonstrate an operator’s degree of virtuosity in preventing and reducing FLW.

The WASTELESS Blockchain will host an electronic ledger, developed on the basis of the FLW Standard of the FLW Protocol (the first international standard for measuring and monitoring food loss and waste), in which food business operators can enter and monitor data and information related to their processes and side streams, including FLW. The data entered is reported based on the Lansink scale and the Waste Hierarchy, to demonstrate an operator’s degree of virtuosity in preventing and reducing FLW.

The Blockchain aims to be a publicly accessible platform for innovation, following OpenTimestamps standards to confirm when data is added, thereby deterring fraud by monitoring other participants in the food supply chain and related stakeholders.

Surplus Stock Measurement and Management Tool

Developed by FAZLA GIDA

Surplus Stock Measurement and Management Tool will enable food chain retailers to identify the food waste at source and plan their procurement and operational processes to eliminate food waste by measuring it. Company-based information will be kept in a product-based cumulative structure and analysed based on region, city, and Storage Keeping Unit (SKU) group. The first part of the tool aims to provide more reliable and validated food waste data at the retailer level. The main purpose of this development represents SKU-based exploratory data analysis by establishing a relational database structure within SKU, regional-based, season-based, etc.

The second part of the tool, the Management System, will be coded in line with the Food Recovery Hierarchy. The Food Recovery Hierarchy principle will be coded into the system as a part of the decision-making process. As a result, the system will create lists of products informing the beneficiary if they are suitable for human consumption (e.g. resell, donation), animal feed, biogas production, or recycling.

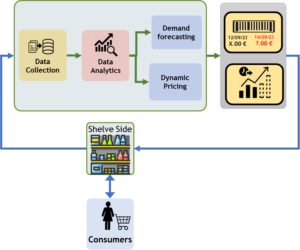

AI-based data driven approach for FW measurement

Developed by AITOWN

This tool aims to develop and implement advanced AI-driven models through continual learning strategy for dynamic pricing and demand forecasting. The primary objective is to figure out how to reduce fresh food waste and potentially turn it into business efficiency enhancement to encourage the retailers to engage more effectively with the sector. By using such a system both the retailers and the society would benefit from it.

This tool aims to develop and implement advanced AI-driven models through continual learning strategy for dynamic pricing and demand forecasting. The primary objective is to figure out how to reduce fresh food waste and potentially turn it into business efficiency enhancement to encourage the retailers to engage more effectively with the sector. By using such a system both the retailers and the society would benefit from it.

This collaboration focuses on creating a sustainable, efficient retail model through the integration of cutting-edge AI technologies, aimed at optimizing shelf availability and pricing strategies in retail environments.

Automatic system for FW assessment at household

Developed by JSI

This tool, which is tailored to everyday use, supports the measurement of food waste in households and is intended to improve and validate existing methods such as surveys.

This tool, which is tailored to everyday use, supports the measurement of food waste in households and is intended to improve and validate existing methods such as surveys.

The tool includes a set of features to measure and estimate various types of food waste generated in households. The developed tool will be demonstrated on a representative sample of households to ensure its reliability and applicability.

The core of this tool is a user-friendly scale complemented by a dedicated application for cell phones that enables seamless data collection and transfer to a centralized database. The data collected is then analysed and the results obtained are extrapolated to a wider population, allowing a more comprehensive evaluation of the parameters traditionally determined with questionnaires and interviews.

Computer vision-based image analysis

Developed by HACETTEPE

Computer Vision-Based Image Analysis Tool is an innovative tool analysing the colour change of the foods in the fridge to correlate this information to the food loss and waste at household level. This tool deals with colour measurement from the 2D image of 3D fresh fruit and vegetable. The system takes the pictures of the selected fruit or vegetable, analyses the image and detects the colour-based deterioration, if any. The deterioration is calculated as area percentage. Finally, this information is correlated to the weight of these fruits or vegetables.

This technology will also be adapted to the meat supply chain to evaluate the meat quality according to their colour for further processing.